Your systems must be finely tuned to operate well. METERYX collects production data and assists you in optimizing processes in real time. Alerts are sent to you when disturbances occur. Real-time analysis ensures supervision of ongoing processes and trend detection. Focus on your tasks and rest assured, METERYX keeps an eye on things.

Target Audience

Designed for companies aiming for effective process control to be responsive to anomalies that disrupt their systems. Data collected by the sensors is stored and analyzed to optimize system parameters accordingly.

What is METERYX ?

METERYX assists factory operators in achieving the full potential of processes and provides assistance to react to changing conditions.

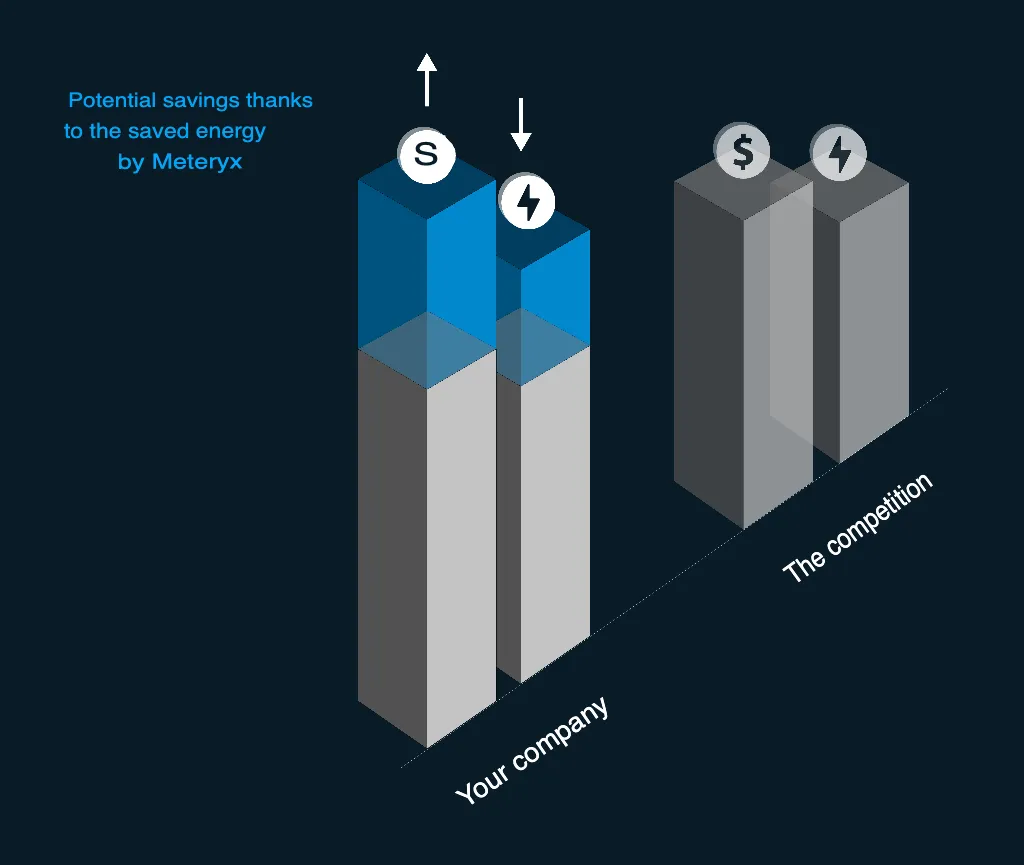

METERYX helps establish and achieve performance goals that will make your company unbeatable, leaving the competition far behind.

METERYX is a modular system consisting of:

Connected sensors

Connection to existing systems

External data acquisition

Custom visualization elements

Process analysis module

Energy analysis module

Connecting to systems present in your factory as well as external services makes it possible to create dashboards and metrics. This allows you to assess the overall performance of your factories, react in case of breakdowns, and better plan the next steps of your growth.

Why use METERYX ?

Real-time Data

With METERYX , the factory manager will have access to the possibilities brought by real-time monitoring as well as historical production tracking. These allow the manager to focus on operations optimization and energy management. Historical data helps in investment decision-making. In addition, energy data analysis allows better control of production costs.

Simplified Analysis and Manipulation

Our system METERYX allows the scientist to define a simple relocation of the sensors. The capture frequency and correlation with existing system data are simple, allowing for rigorous and efficient analysis.

Custom Alerts

The person responsible for maintenance will always be warned by warnings or trends when a process is out of control. The creation of customized alarms and the development of 'trends warnings' make optimal factory supervision and analysis possible. Accessibility to real-time performance indicators facilitates preventive maintenance, thereby reducing the possibility of breakdowns and production stoppages.

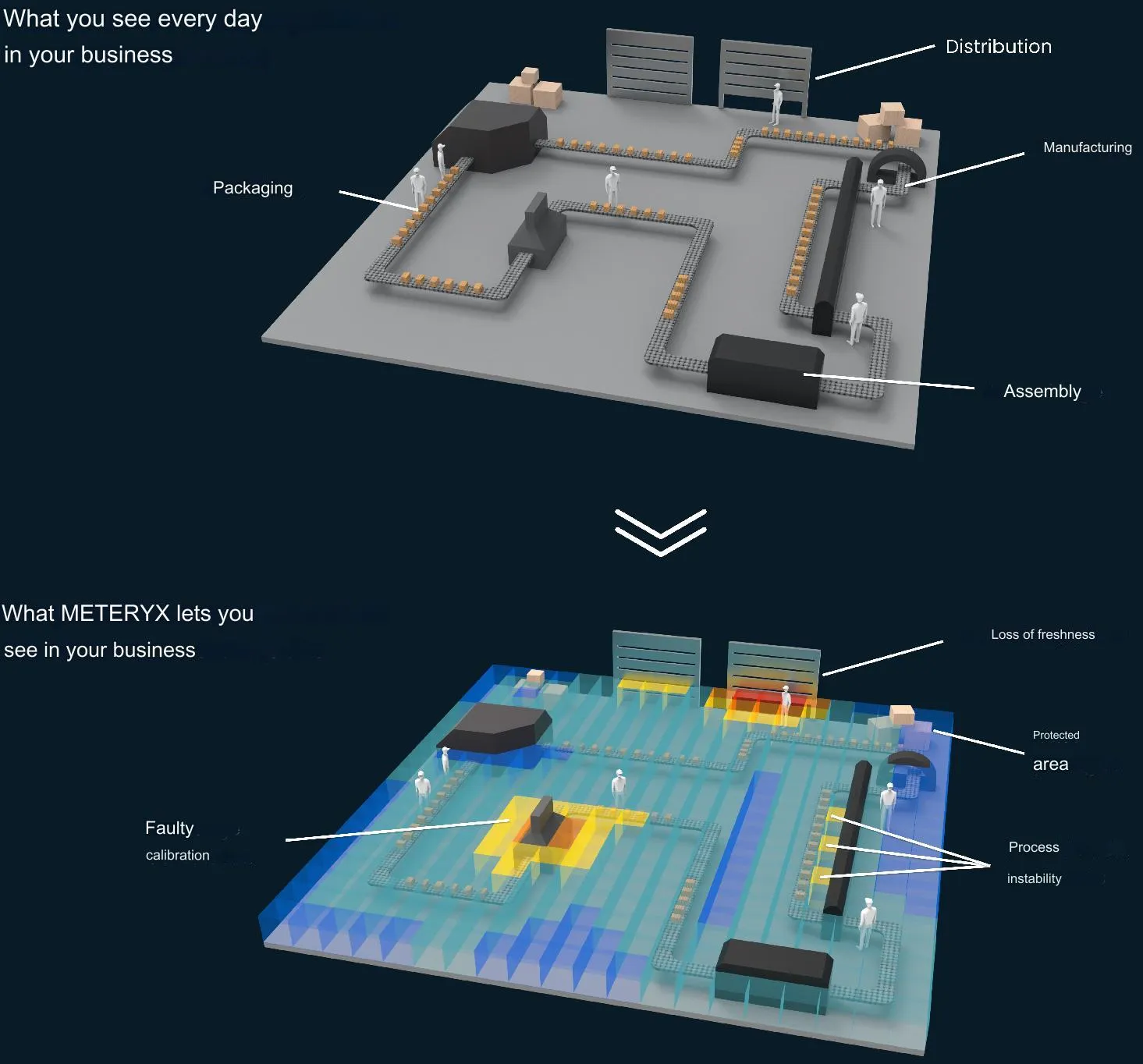

In Practical Terms, What Does It Do?

In addition to real-time alerts, METERYX analyzes historical data, makes comparisons, detects trends, and proposes improvements. This is what sets METERYX apart from the competition.

By suggesting minor adjustments to the parameters, you'll have everything at hand to optimize your factory and processes. You'll avoid repeated and long-lasting malfunctions. METERYX helps you stay in control and maintain the course towards process optimization.

Over the months, you'll track the evolution of your production costs. Savings accumulate, and your competition struggles more and more to keep up.

Isn't that what you want to achieve?

METERYX is beneficial for:

Factory management

Factory management , concerned about equipment profitability.

METERYX allows checking performance in real-time, making historical comparisons, and quickly detecting and correcting any deviations from the system.

Process team

Process team, which improves its understanding of processes for continuous improvement. It seeks to determine metrics that validate and ensure the quality of the final product. To achieve this, this team benefits from more quality data, the ability to relocate measuring points, and an accelerated acquisition frequency to better document complex processes under study.

The maintenance team

Maintenance team , which must be aware of what is happening in the factory at all times to detect failures and take action quickly. METERYX makes all relevant information accessible in real-time and suggests solutions and optimization paths.

Process

METERYX is a process optimization service. An initial assessment determines the parameters to monitor in your factory and indicates the extent of the solution to be deployed. Once the sensors are configured and strategically installed in the studied environment, you access data meaningfully and efficiently through a customized interface.

In no time, you'll have access to the details of ongoing operations in your factory and the certainty that everything is going as planned. You'll be notified if there's a change before it's too late to act.

Your factory is equipped with complex systems. Your processes are at the center of your operations.

Have your systems evolved with your needs?

METERYX is here to help !

Would you like to improve the efficiency of your process?

Contact us for a quick study of your energy consumption!By comparing your energy consumption according to your industry, you can discover how the system METERYX can help you stand out in the industry and save energy in your business.

CONTACT US